Elevate Your Designs

Performance Beyond Compare | Endless Design Horizons

As a trusted material supplier to high-reliability industries worldwide, our conductive inks exceed industry standards. With unmatched stretchability and conductivity, they elevate designs while meeting stringent reliability requirements. Our unique manufacturing process also supports companies in hitting sustainability targets with every order.

New Levels of Performance

Our materials enable advanced performance in a broad range of industries and applications from wearable devices to surface mount technology. Our superior dispersions enable more consistent, durable, conductive, and sustainable products.

More Stretchable

More Conductive

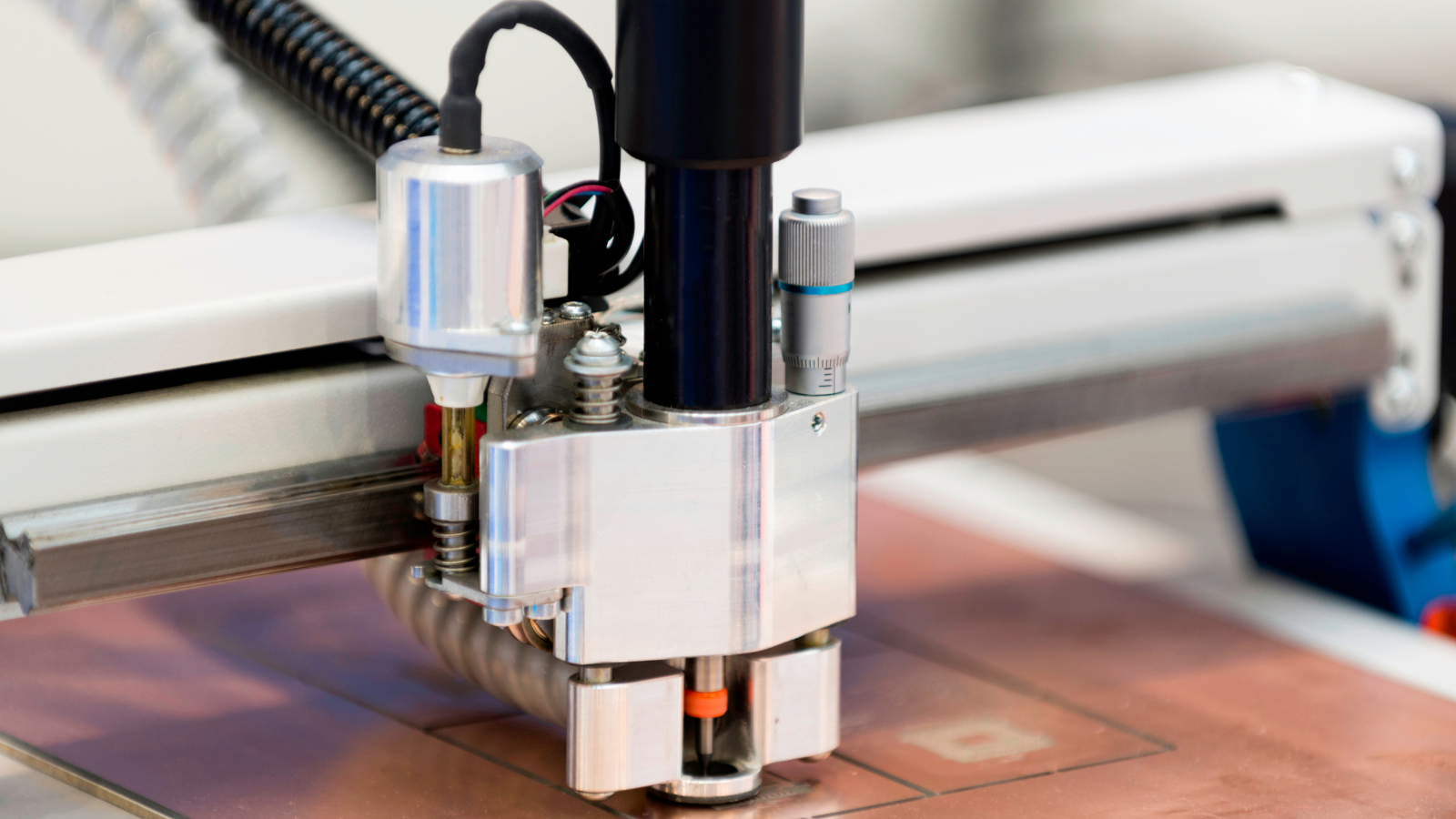

Enclosed Production Process

Empowering Industries

Innovation, Excellence, and Proven Expertise

Medical

Collaborating with medical device OEMs—as well as pharmaceutical and healthcare companies—ACI Materials experts work with customers to deliver innovative flexible electronics that enable products of the future.

Sports & Fitness

Through collaboration with performance apparel companies, sporting goods manufacturers, and fitness technology innovators, we are dedicated to delivering state-of-the-art products that shape the future of sports and fitness experiences. We leverage our expertise to seamlessly blend technology with innovative fitness products.

Mobility

From transportation to battery management, we are committed to advancing the way people and data move, and ushering in a new era of connected, efficient, and eco-friendly mobility.

From Concept to Creation

Explore the Possibilities Created Through ACI Materials Across Applications

Revolutionize warmth with innovative and stretchable printed heaters.

Experience superior performance with thin, functional antennas.

Elevate biometric monitoring with comfortable, stretchable, and flexible biometric sensors.

Enable high-performance devices with sustainability in mind.

Recover and heal faster with comfortable and convenient e-stimulation.

Working on something different?

Take your big idea and make it reality. Our team of experts and vast network of partners can help get your product ready for manufacturing.

Materials that Enable Tomorrow's Technology

Greener Manufacturing Processes

Printed electronics are produced through additive manufacturing processes, such as screen printing or inkjet printing, which consume fewer resources, generate less waste, and reduce the need for harmful chemicals.