Innovation

Revolutionizing Material Manufacturing

ACI Materials is not just a manufacturing and development company; we are architects of the future, shaping technology and driving innovation through our advanced materials. Our team pushes the boundaries of what is achievable in materials science and printed electronics. We innovate alongside our clients to produce new design possibilities.

Cavitation — Our Patented Platform Technology

Elevating material quality through our unique proprietary manufacturing process and taking performance to levels unattainable through traditional mixing methods. Our process results in better dispersion and higher solids loading. Generating the most homogenous ink on the market.

The Possibilities Are Endless

Dive into the unique capabilities of our conductive inks and explore different real-world applications.

White Paper: Cavitation

An in-depth explanation of how our patented cavitation process improves the electrical and mechanical properties of functional materials.

Product Sheet: Alchemy Inks

Comparison of the three main types of conductors and how our semi-sintering alchemy inks offer the best performance of all.

Alchemy Conductive Inks Enabling Next-Generation Flexible and 3D Electronics

Stretchable Inks that Meet the Demands

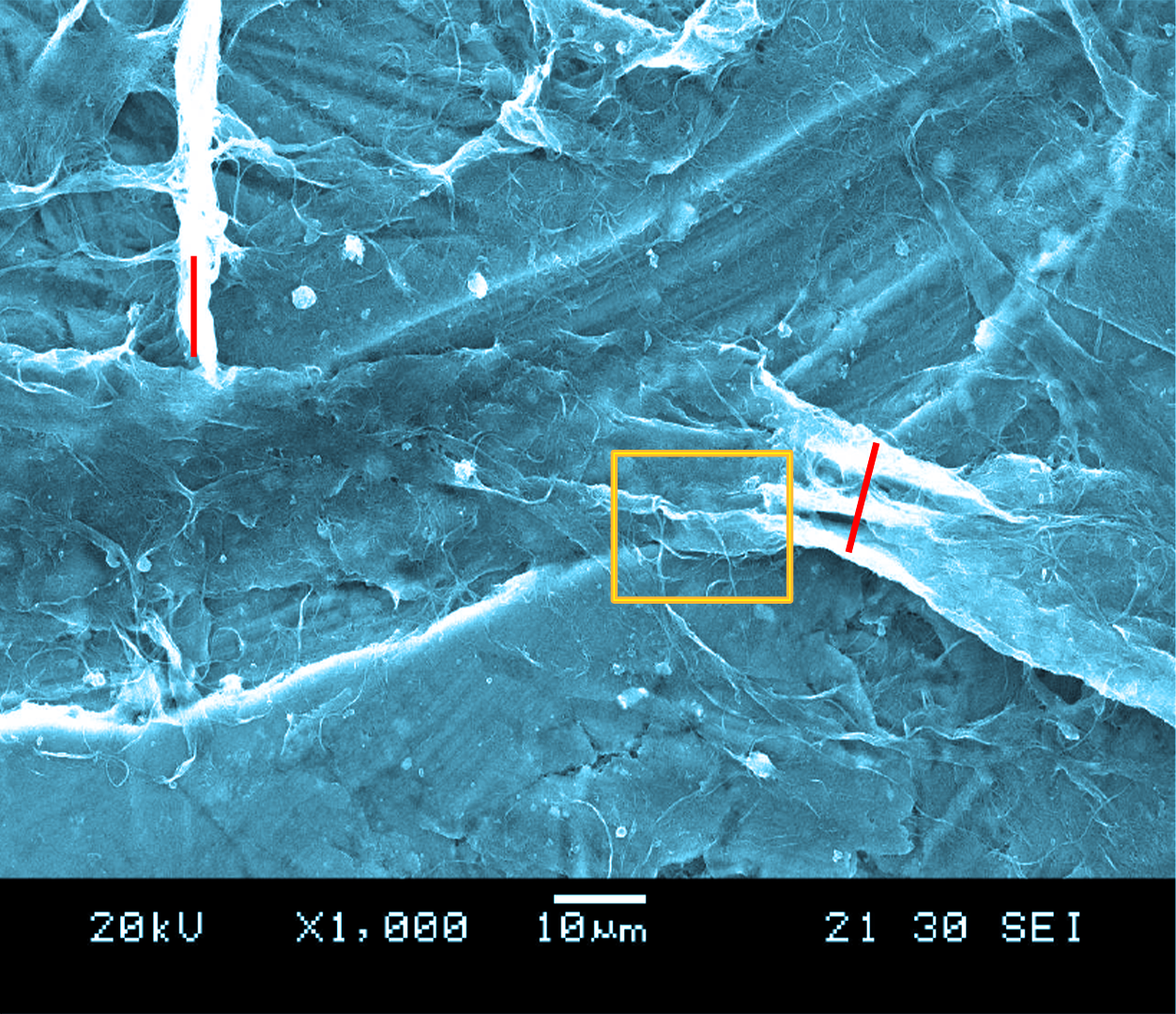

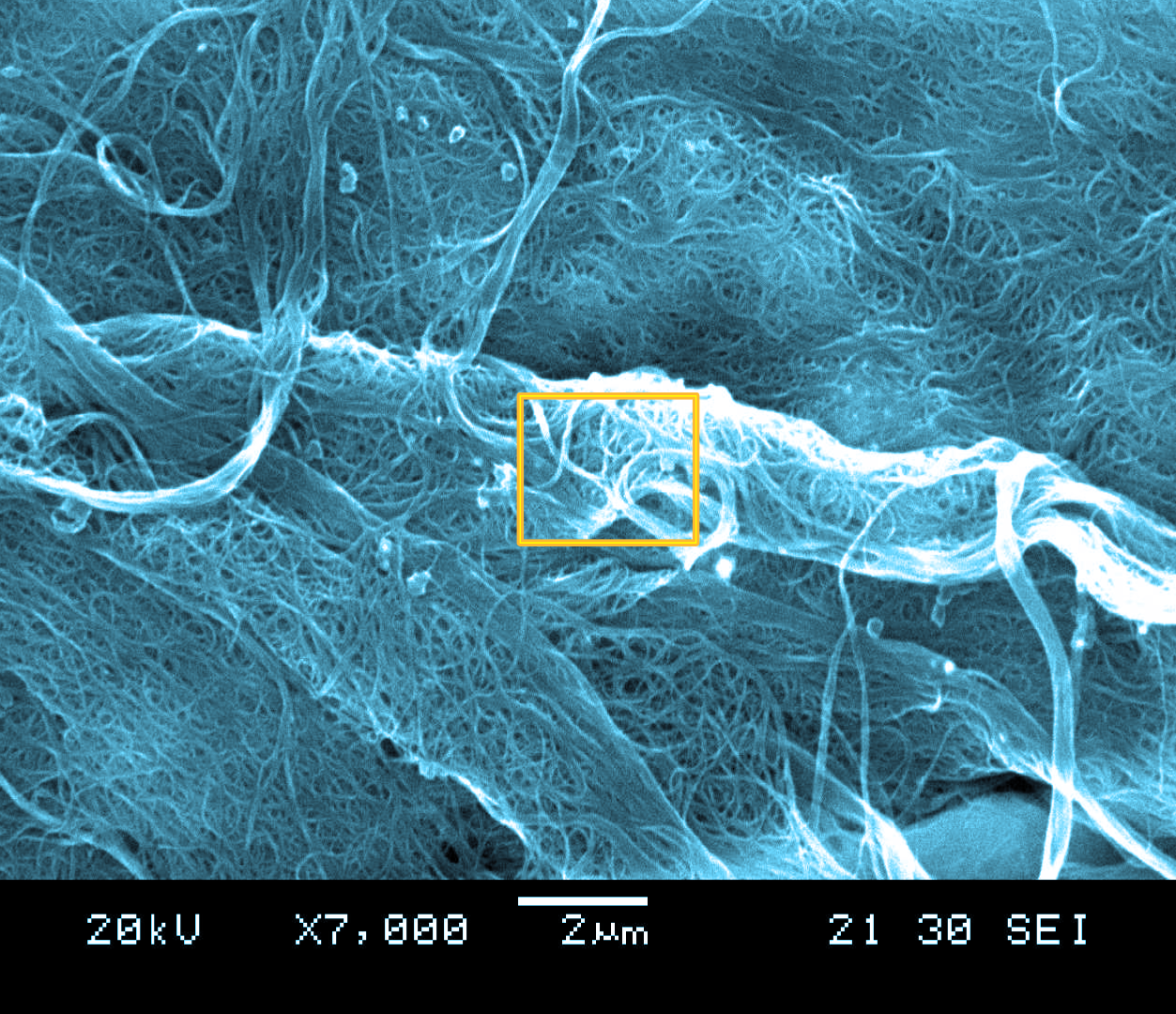

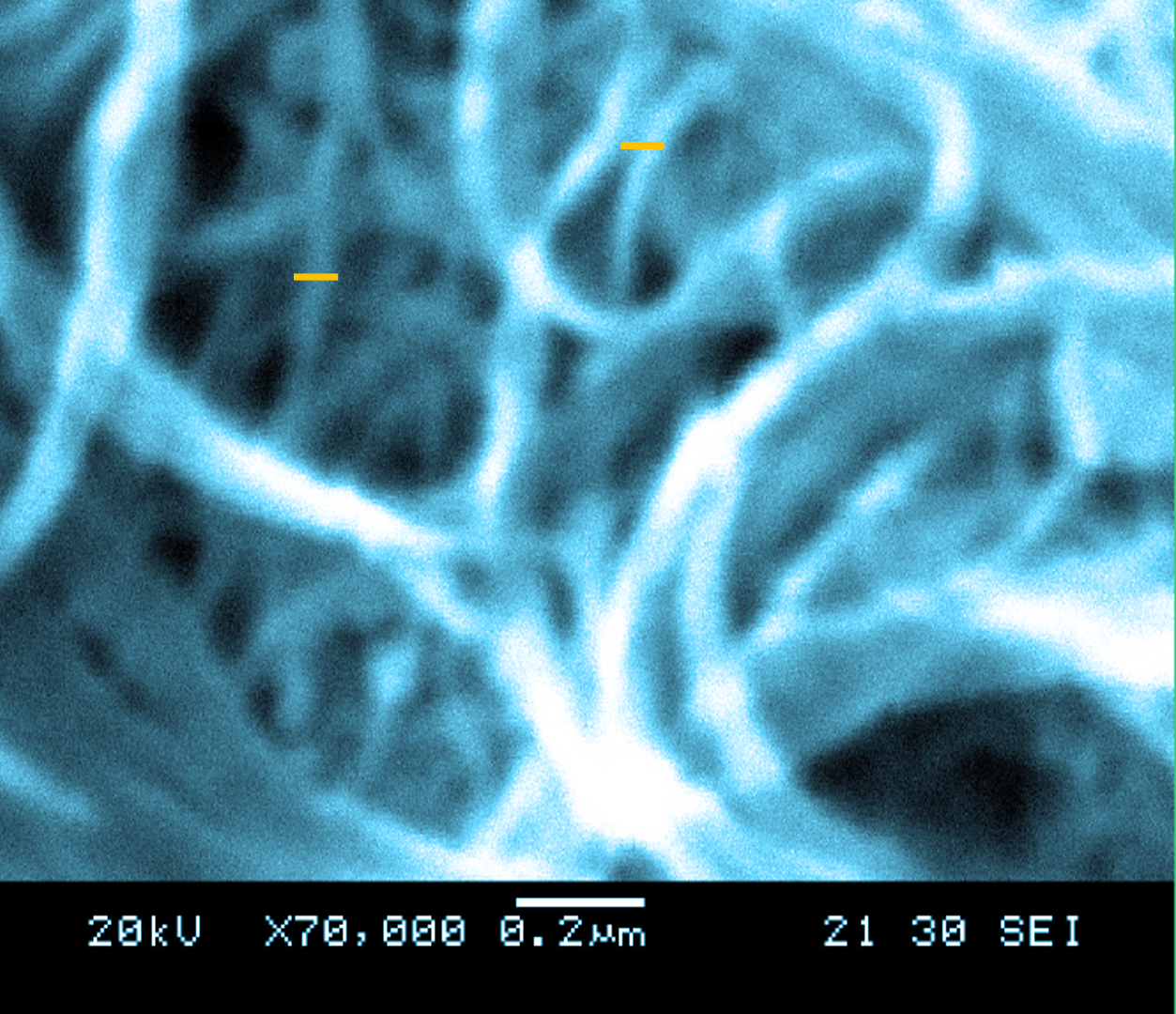

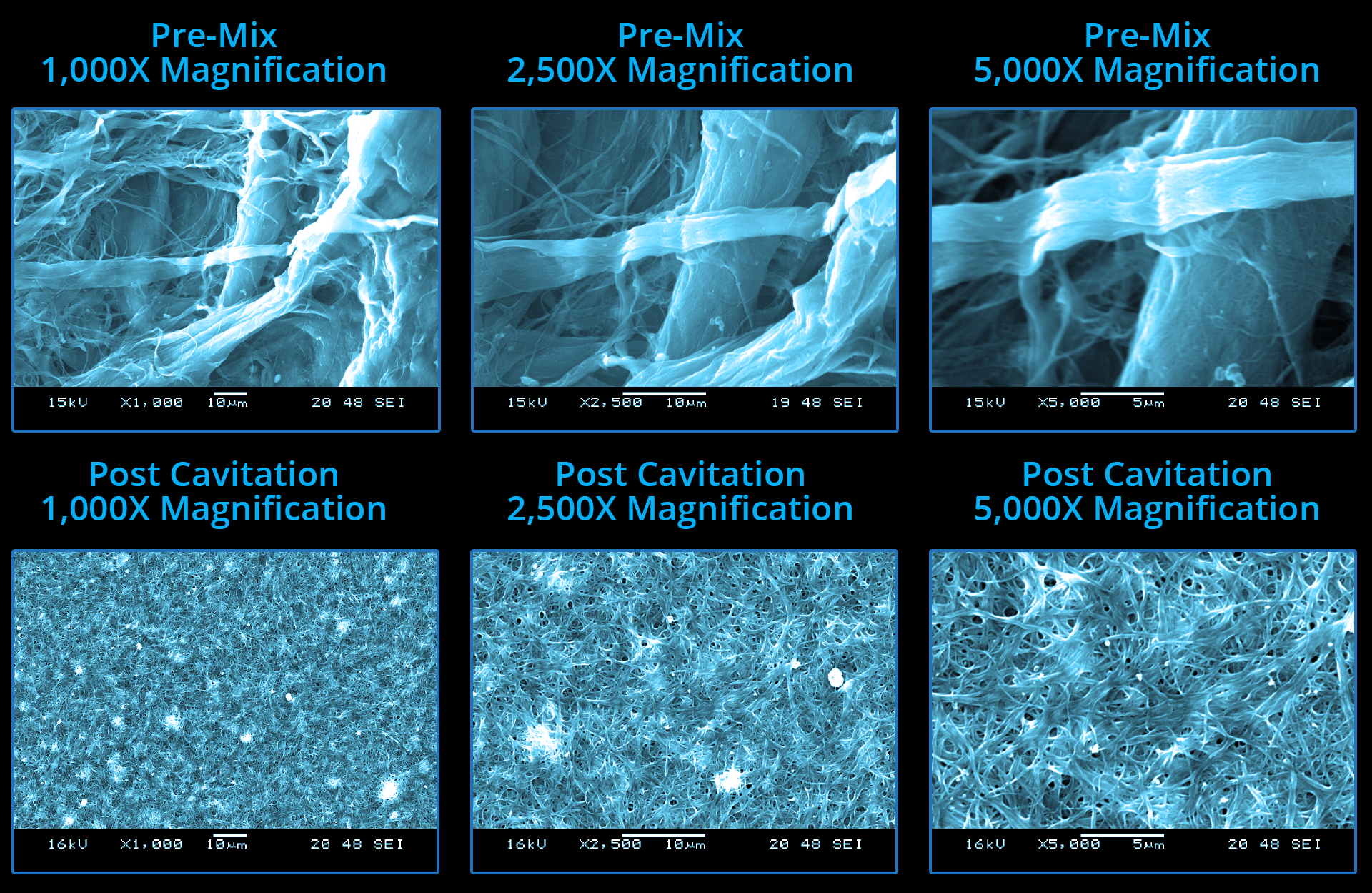

Carbon Nanotubes - The Unbundling Challenge

Pre-cavitation mixing samples show large bundles of chords of SWCNT. Chords widths rang in the 50-200nm (nominal diameter of individual SWCNT ~2.5nm, so 20-80 tubes wide). Due to the immense surface area of the SWCNT and the Van der Waal attractions, the SWCNT have a propensity to bind together strongly. This makes it very challenging to unbundle the chords, without causing significant damage to the SWCNT aspect ratio. The SEM has a limited capability to assess the nano structure of the chords, which can be revealed using other imaging techniques that ACI Materials currently does not have. It is also uncertain that dried films would be able to remain un-aggregated as the solvent vaporizes. It is likely that much of the CNT content would stick back to each other, due to the ultra-high surface area.

Red bars indicate 10µm scale, showing that some bundles are greater than 10µm in diameter and greater than 30µm in length.

The 7k X magnification shows the nature of how the bundles are made up of chords.

The 70k X magnification shows the scale of the chords. The yellow ticks are ~50nm in width.

Cavitation - The Unbundling Solution

Through controlling the cavitation processing parameters, we are able to effectively unbundle CNTs while keeping their aspect ratio intact. We can control the amount of unbundling that occurs so that the outcome is a balance of targeted Volume Resistivity and Sheet Resistance, as well as desired rheological properties.

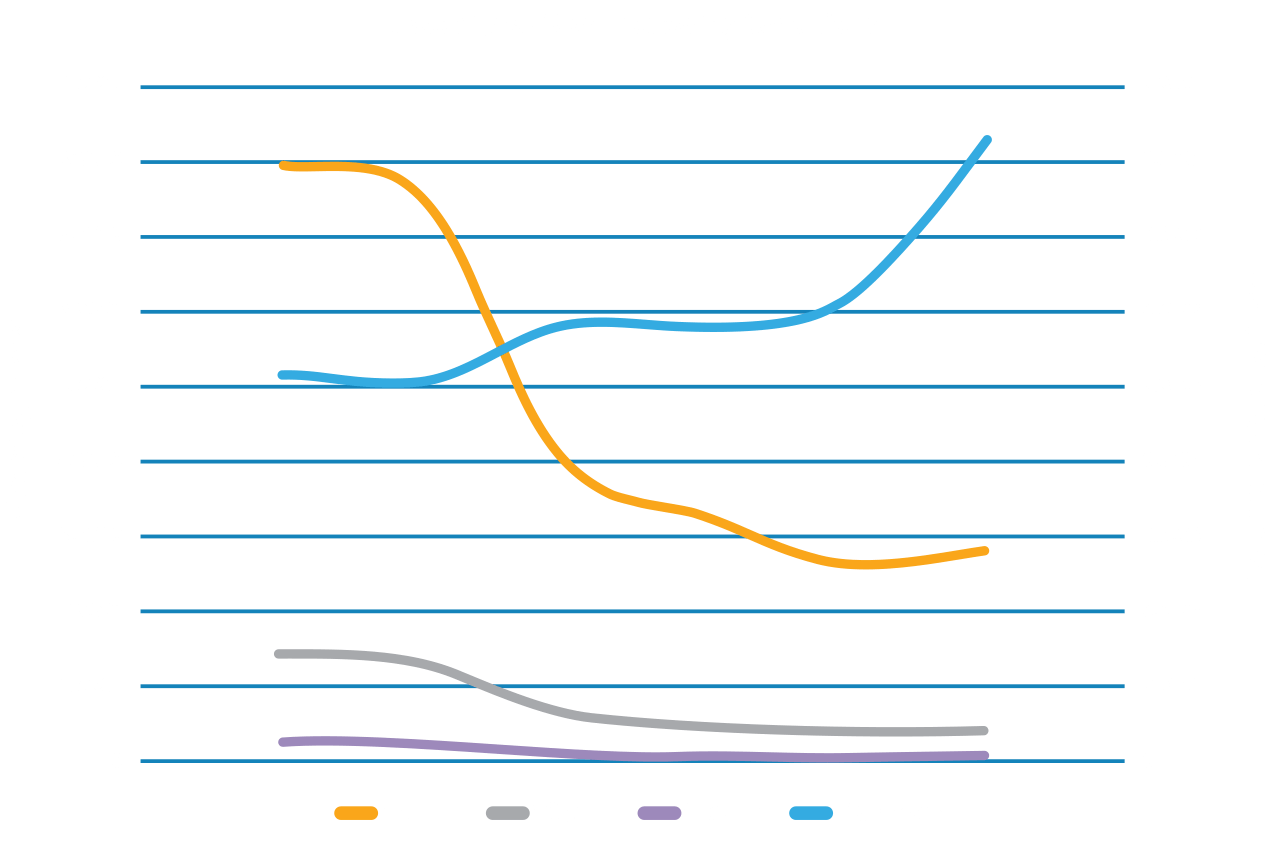

Viscosity & Volume Resistance

Through ACI Material's precise control of cavitation processing parameters, it is able to effectively unbundle CNTs while keeping their aspect ratio intact. The process can control the amount of unbundling and dispersing that occurs, so that the outcome is an optimal balance of volume resistivity and desired rheological properties.

The graph demonstrates how processing control allows for ACI to choose which conditions give the best electrical performance at an appropriate viscosity for the given application. These volume resistivity values are evaluated from dried, stencil printed films of pure SWCNTs at various processing conditions.

Masterbatch Concentrates

ACI disperses high value functional fillers in high concentrations which can be used as additives to enhance performance.

ACI Masterbatches contain materials that are difficult to effectively disperse such as Carbon Nanotubes and Boron Nitride. We are able to disperse and exfoliate challenging materials in a variety of solvents and polymers.

The ACI dispersion technology offers superior control of top size particles through effective elimination of large agglomerates.

Contact us if you would like to discuss dispersions of high value, difficult to disperse functional fillers.