About

ACI Materials is an advanced material supplier providing technological solutions and advantages across industries and applications. Our innovative materials are created by combining a patented cavitation process with decades of formulation experience.

Meet the ACI Team

Our Commitment to Sustainability

ACI Materials is committed to fostering a sustainable environment for our people and our customers. Our patented cavitation process is an environmentally friendly option when compared to three roll mills and other bulk mixing processes. Our inks, pastes, and conductive materials are manufactured with significantly less release of volatile organic compounds (VOCs), diminishing waste. These materials are then used in an additive manufacturing process, which produces less waste than subtractive manufacturing. The additive manufacturing process is a more environmentally conscious process because, when compared to subtractive processes like PCB manufacturing, it eliminates water usage as well as the waste stream of water containing acid and copper.

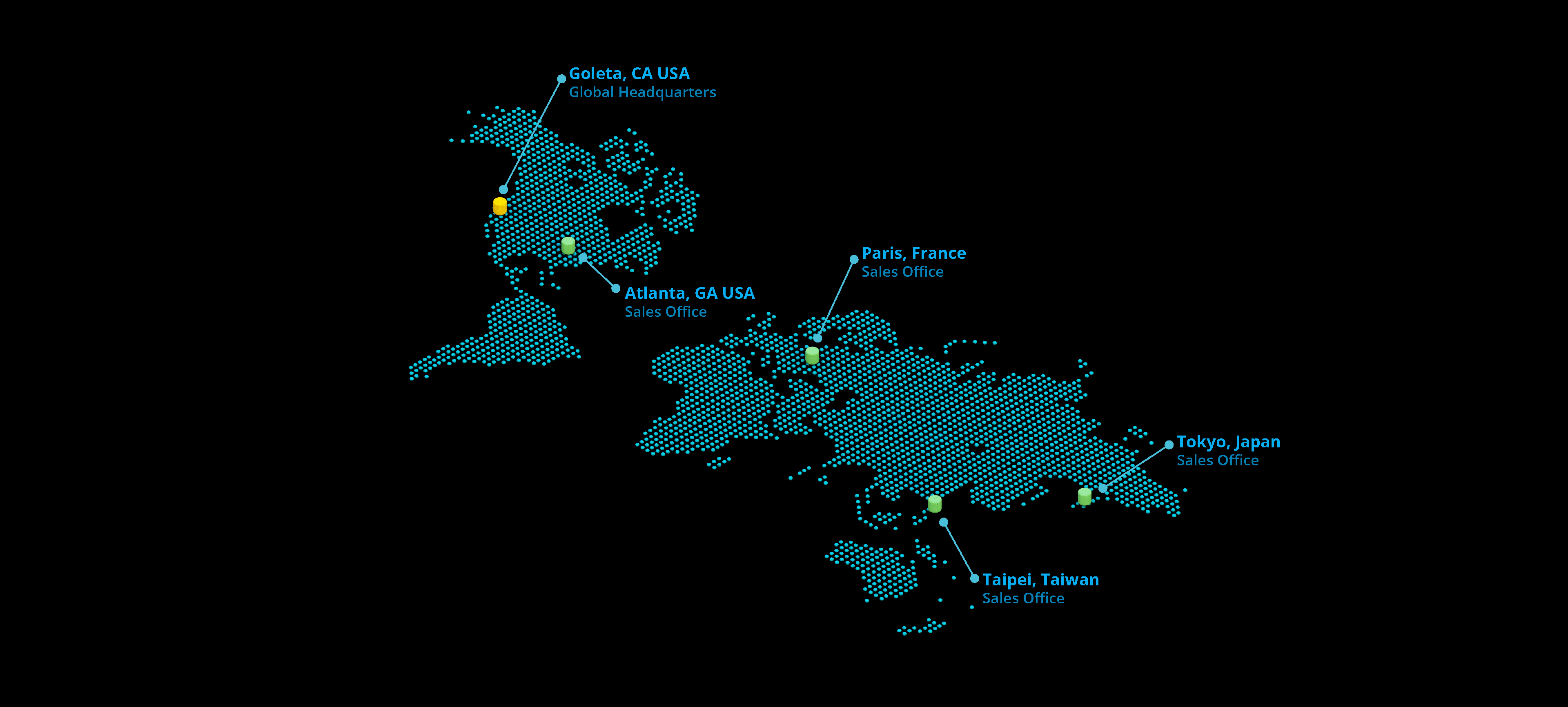

Global Footprint