Conductive Threads vs. Conductive Inks: Which Is Best for Wearable Applications?

There are two popular materials currently on the market used to make wireless wearable technology: conductive threads and conductive inks. How do you know which to choose for your wearable application? While both conductive inks and conductive threads offer benefits compared to traditional and bulky wires, there are some crucial differences between the two materials.

Conductive Threads vs. Conductive Inks

Conductive threads (or yarns) are typically made from a range of materials, including metal, carbon, and conductive polymers. These materials are spun into threads that can be woven or knit into fabrics, creating a wearable conductive material.

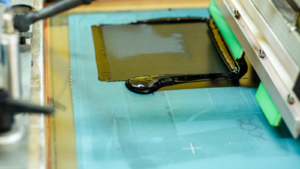

In contrast, conductive inks are liquid or paste-like materials used to create conductive pathways on a surface. Conductive inks are made from various materials, including silver, copper, and carbon. They can be applied to a surface using printing methods like screen printing or inkjet printing. Conductive inks are typically used to create printed circuit boards, but their use in e-textiles is growing because of their ability to stretch and flex.

Wearable Applications

If you’re looking for wearable clothing that can stretch and flex with the user, conductive inks are the right choice. Conductive threads struggle to maintain their shape and conductive properties when stretched.

Conductive threads can sometimes be difficult to integrate into fabrics because of their rigidness. In an application where wearable sensors are tracking biometric data on an athlete, a material that bends and flexes as the athlete exercises is best. A conductive thread would break as the athlete vigorously moves. It can also be uncomfortable for the wearer as the threaded sensors would feel different than the normal athletic wear.

Conductive inks are screen printed onto thin, flexible substrates like TPU and then adhered to the garment the athlete is already comfortable wearing. As the athlete moves, biometric sensors made with conductive inks move with them.

Benefits of Conductive Inks over Conductive Threads

The greatest benefit that conductive inks offer over conductive threads is their ability to stretch and flex. But conductive inks offer several other advantages over conductive threads, including:

- Reliability

- Versatility

- Durability

Conductive threads are generally less conductive than conductive inks since they are made from materials that are less conductive than the metals and other materials used in conductive inks. This means that conductive threads are not suitable for applications that require high levels of conductivity. As a result, conductive inks tend to be more consistent and less prone to defects than conductive yarns.

While conductive threads have their own advantages, they are not as versatile as conductive inks. Conductive inks can be printed or screen-printed on various substrates, whereas conductive threads typically need to be woven or knit into fabrics. The integration process for conductive threads is more labor-intensive and less efficient than conductive inks. To integrate conductive inks into fabric or garments, all you need is a heat press. Conductive inks are ideal for use in a wide range of applications. Conductive inks can be used to make electronic devices from printed circuit boards to stretchable heated e-textiles.

Conductive inks are also more durable than conductive threads because the ink is protected by an encapsulant. These encapsulants provide a barrier against moisture or other environmental factors that could potentially damage the printed circuit. The protective barrier allows for a wearable device powered by conductive inks to be washable and last longer than conductive threads that are exposed to the elements like sweat and water.

Switch to Conductive Inks Today

While both conductive inks and conductive threads have their benefits, conductive inks are generally considered to be the better solution for wearables. Conductive inks are more stretchable, comfortable, and durable than conductive threads. Reach out to our team of conductive ink experts today to switch your wearable project from conductive threads to conductive inks.