How Flexible Circuits Are Shaping a Sustainable Electronics Industry

In an era where sustainable practices and environmental considerations are paramount, old manufacturing processes are being replaced with new, innovative technologies. The electronics industry is no exception. Circuit boards form the backbone of countless devices, enabling the seamless flow of electric signals. Printed circuit boards (PCBs) have been the standard choice for decades, but emerging alternatives, such as flexible circuits, are a greener option for a more sustainable future.

Printed Circuit Boards (PCBs)

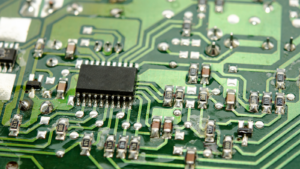

Printed circuit boards are flat boards made of non-conductive substrates (typically fiberglass) with conductive pathways etched onto them. They serve as the foundation for electronic components, allowing electrical connections and mechanical support. PCBs have been widely used in countless devices, from smartphones to automobiles.

The Environmental Impact of PCBs

While PCBs have played a crucial role in advancing technology, they come with environmental concerns. PCBs use a subtractive manufacturing process, which produces excess waste. To create a PCB, a non-conductive material, typically fiberglass or epoxy resin, is used as the base substrate. Layers of copper foil are then laminated onto the substrate. A chemical-resistant material called the resist is applied to the copper layer, and the circuit pattern is printed on it. The exposed copper is then etched away using corrosive chemicals, leaving behind the desired copper traces.

The corrosive chemicals used during the manufacturing process can pose a threat to human health and the environment. Proper safety attire, such as gloves, goggles, and a face mask, should always be worn when manufacturing PCBs.

Flexible Circuits

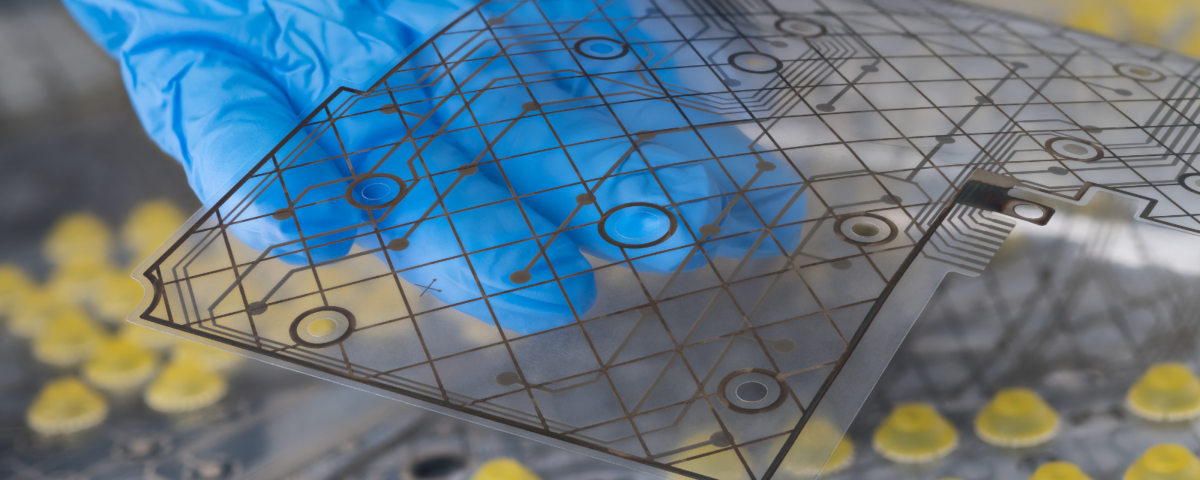

Flexible circuits, also known as flex circuits or flexible printed circuit boards, offer a compelling alternative to traditional rigid PCBs. These circuits are made from conductive materials and flexible substrates like polyimide or polyester, allowing them to bend, twist, and conform to various shapes and sizes.

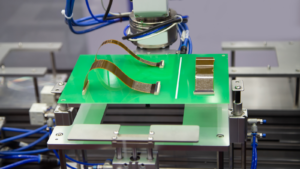

Flexible circuits are made through an additive manufacturing process, which produces little to no waste. Conductive silver or carbon-based inks are screen printed or 3D-printed onto the substrate to create a flexible circuit. Conductive inks offer the ability to create intricate circuit patterns. 3D-printed circuit structures also allow for volumetric savings in areas where traditional PCBs fall flat.

One key advantage to flexible circuits lies in their adaptability and versatility, enabling them to integrate into products with complex form factors. Flexible circuits can be used in several applications, including IoT devices, RFID technology, smart tags and new technologies like wearable devices and curved displays.

Environmental Benefits of Flexible Circuits

-

Reduced Material Usage:

Flexible circuits require fewer layers and, therefore, fewer materials compared to PCBs. This also means cost savings for manufacturers. Although conductive inks may be more expensive than materials used for PCBs, less material is needed for flexible circuits and a more expensive ink would cost less per device.

-

Energy Efficiency:

The flexibility of these circuits enables more compact designs, leading to smaller and lighter products. Reduced size often translates to decreased power requirements, resulting in improved energy efficiency and reduced carbon footprint throughout the product lifecycle.

-

Cleaner Manufacturing Processes:

Flexible circuits employ cleaner manufacturing techniques compared to traditional PCBs. They utilize additive manufacturing processes, such as screen printing or inkjet printing, which consume fewer resources, generate less waste, and reduce the need for harmful chemicals.

-

Extended Product Lifespan:

Flex circuits offer improved durability, withstanding repetitive bending and flexing without compromising functionality. Some conductive inks, like ACI Materials’ Alchemy Inks, offer superior hard crease survivability. This durability reduces the likelihood of circuitry failure, ultimately extending the lifespan of the product and reducing electronic waste.

New and Greener Possibilities with Flexible Circuits and Conductive Inks

Flexible circuits unlock endless possibilities for product design and innovation. Their adaptability allows for seamless integration into wearable technology, medical devices, IoT applications, and so much more. By replacing rigid PCBs with flexible alternatives, manufacturers can design products that are lighter, more comfortable, and better aligned with sustainable practices.

As the world becomes increasingly conscious of environmental challenges, embracing greener technologies in every industry is crucial. Flexible circuits offer a sustainable alternative to traditional PCBs, providing numerous environmental benefits, from reduced material usage to cleaner manufacturing processes and extended product lifespans.

ACI Materials offers the necessary materials to get started on your next flexible circuit project. Contact our team today to learn more about the benefits of our Alchemy conductive inks.